How Paving Bricks can Save You Time, Stress, and Money.

Wiki Article

9 Simple Techniques For Paving Blocks

Table of ContentsThe Ultimate Guide To Paving StonesPaving A Way Meaning Fundamentals ExplainedPaving Fundamentals ExplainedPaving Blocks Fundamentals Explained

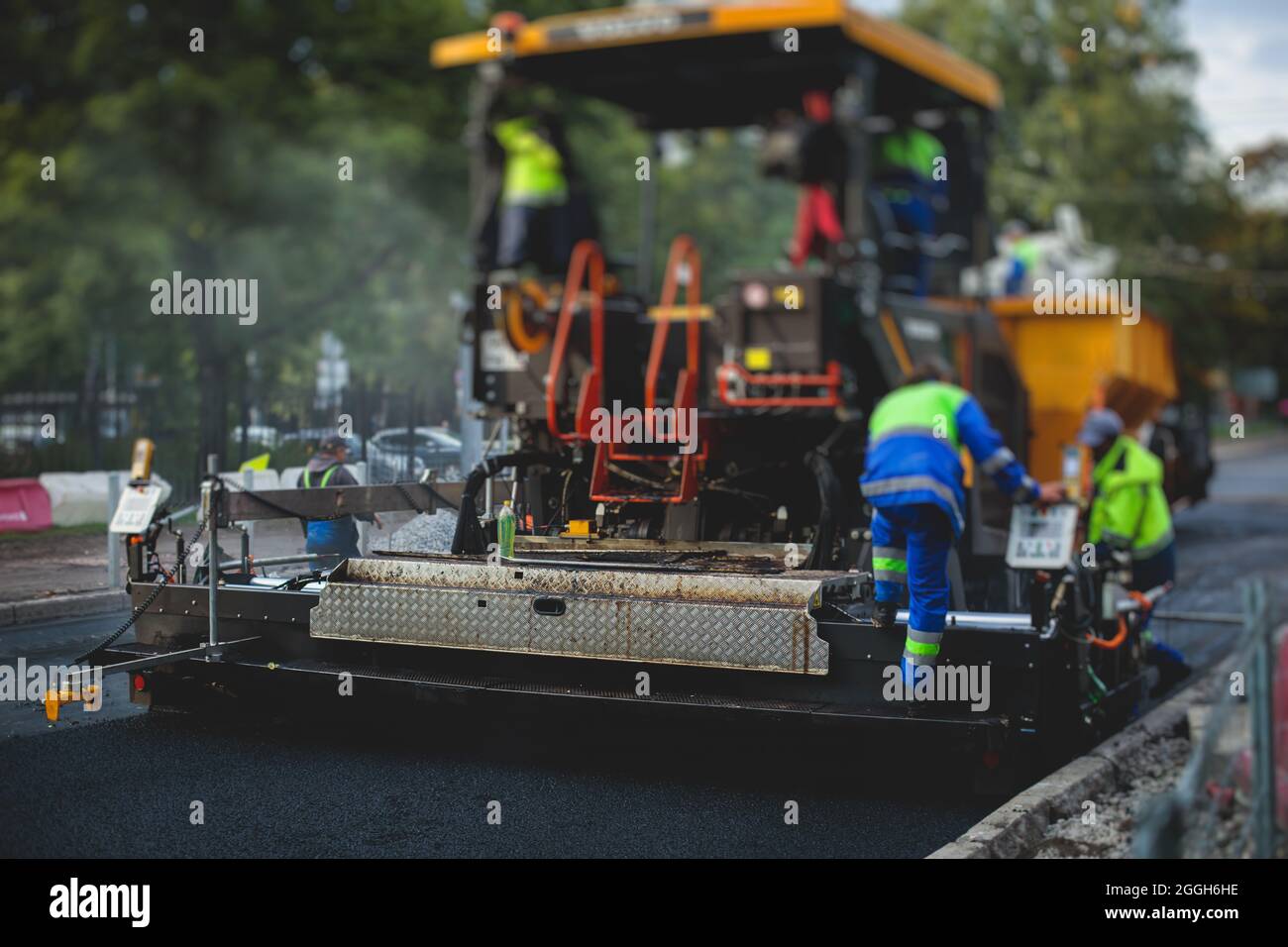

Asphalt concrete, additionally referred to as black sealing agent has been utilized for roadway construction for centuries. Asphalt is a mix of accumulations, binder, and also filler, made use of for building and maintaining roads.

Asphalt paving is a blend of 2 primary active ingredients:1) Aggregates2) Asphalt binder, The accumulations have around 95% of the complete blend by weight. Aggregates are blended with 5% of asphalt binder to generate asphalt sidewalk. The accumulations and asphalt are heated to a proper temperature level and also blended in a processing plant efficient in creating specified materials.

The product is then compressed to the called for level by hefty, self-propelled rollers, creating a smooth pavement training course. Depending upon the factors such as ambient conditions, to attain ample density, care is been taken that mix temperature does not fall listed below optimal compaction temperature while the product is compressed. 1) Hot mix asphalt 2) Warm mix asphalt 3) Half-warm mix asphalt 4) chilly mix asphalt, Warm mix asphalt (HMA) has a laying temperature level over 150C, it is just one of the standard paving approaches utilized.

The Best Guide To Paving Stones

e., 50% and also 10to30%. It contains the 5 layers discussed below (From base to top)1) Sub-Grade (150-300mm)The subgrade is a layer of all-natural soil prepared to get the layers of the sidewalk as well as is a base of all the repayment layers. All the stress of the above pavement layers is moved to Sub-grade.

2) Sub-base (100-300mm)It is the layer of the product between the Sub-Grade course and also Base-Course. The key functions of the sub-base are to offer architectural support, improve drain, and reduce the intrusion of fines from the sub-grade in the sidewalk structure.

When it comes to the base program, the course is open-graded or has a large air void, the sub-base course with even more fine product can be used as filler in between sub-grade and also the base training course. The course generally includes broken stones, blocks, or aggregates. As the anxieties in a sub-base are a lot lower than those in the base, the material made use of is substandard to those in the base training course.

The 8-Minute Rule for Paving Blocks

Monday, November 23rd, 2015 The decision to have an asphalt driveway mounted at your house is an economic investment. This financial investment ought to offer the finest quality of job as well as materials from the finest Youngtown asphalt service provider. There is a procedure of laying down asphalt and a certified useful content asphalt contractor must follow this procedure so the home owner obtains the proper asphalt required for their driveway.The structure may need to have actually stones included in the ground so it can provide a durable structure. If the structure has a soft basing product or stumps as well as roots, after that this all need to be eliminated initially, after that stones can be included in the area. The structure is among the most important functions of the asphalt.

The warm asphalt is laid on top of the sub-base, and after that rolled uniformly. The surface has a paver and also roller discuss the asphalt so the asphalt is dispersed evenly and also compressed at the exact same time. The sides are hand tamped at a 45 degree angle so it offers the support required for the asphalt.

The Buzz on Paving Blocks

You will certainly be able to walk on the asphalt 24 hours after the asphalt is finished. You can park and drive on the asphalt three days later on. The procedure for asphalt is not quick, yet the delay is worth it in the long run.Milling is the procedure of grinding off the top layer of asphalt or surface area of a road. This is normally carried out in prep work for paving, although there are exemptions where no milling or just partial milling is required. Paving. More about the author Resurfacing is the procedure of putting an asphalt overlay on a roadway, whether or not it has been milled.

Much of the work is done at evening in order to lessen disruptions to traffic - Paving. Although DOT takes actions to decrease the hassle, milling requires trucks, unique machinery and also portable lights. To lessen disruption, equipment is fitted with sound reduction tools and also try this site teams attempt to keep noise to a minimum.

You might require concrete substitute or asphalt substitute. You also may require new asphalt or concrete on a substratum that formerly did not have a prepared surface area.

Report this wiki page